clear all

clc

% Eng. Ammar Aziz Zohaib Hassan Ahmad Bilal Ali Hassan

%-------------------------------------------------------------------------

% Modeling of heat generation and Temperature distribution in machining

%-------------------------------------------------------------------------

%--------------------------------------------------------------------------

%--------------------------------------------------------------

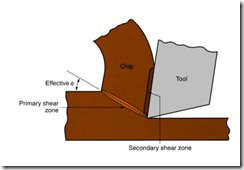

% Heat generated in the Primary and Secondary deformation Zones

%--------------------------------------------------------------

% The tool is standard C2 WC tool

% The chip is Al2024-T351.

hehe = input('Press any numeric key and then enter to start working=');

% Rake face angle of tool is

alpha=input('rake face angle of tool(0 Radians is recommended for turning)=');

rake_face_angle = num2str(alpha);

display(rake_face_angle);

% Coefficient of friction between tool and chp

u = 0.57271;

coefficient_of_friction = num2str(u);

display(coefficient_of_friction);

% Normal friction angle in Radians

% Depends upon the coefficient of friction b/w tool and chip

beta = atan(u);

normal_friction_angle = num2str(beta);

display(normal_friction_angle);

% Thickness of the cutted chip in meters is (found experimentally....)

t2 = 0.000333;

thickness_of_cutted_chip = num2str(t2);

display(thickness_of_cutted_chip);

% Contact length

cntct = 1.5*t2;

% Feed per revolution(in case of turning), in meters is given by

h = input('feed per revolution(0.000165 m/rev is standard)=');

feed_per_revolution = num2str(h);

display(feed_per_revolution);

% Chip thickness ratio is

rat = h/t2;

chip_thickness_ratio = num2str(rat);

display(chip_thickness_ratio);

% Shear angle in the shear plane

% Depends upon the rake face angle and chip thickness ratio

phi = atan((rat*cos(alpha))/(1-rat*sin(alpha)));

shear_angle = num2str(phi);

display(shear_angle);

% Width of the cutted chip in meters

w = 0.00254;

width_of_cutted_chip = num2str(w);

display(width_of_cutted_chip);

% Entering the shear strength of the chip283e6

S = 276e8;

shear_strength_of_chip = num2str(S);

display(shear_strength_of_chip);

% Cutting force in Newtons is given by (Merchant's circle approximation ..)

Fc = 573;

Cutting_Force = num2str(Fc);

display(Cutting_Force);

% Feed or Thrust force is Newtons is given by (Merchant's approximation..)

Ft = 329;

thrust_force = num2str(Ft);

display(thrust_force);

% Shear Force

Fs = Fc*cos(phi) - Ft*sin(phi);

shear_force = num2str(Fs);

display(shear_force);

% Shear area is given by

A_s = (h*w)/sin(phi);

shear_area = num2str(A_s);

display(shear_area);

% Shear stress within the primary zone is

tau = Fs/A_s;

shear_stress = num2str(tau);

display(shear_stress);

% The cutting velocity in meters per second is

Vw= 1.36;

cutting_velocity = num2str(Vw);

display(cutting_velocity);

% heat generation rate per unit depth of cut in primary zone :

Qs =(tau*h*Vw*cos(alpha))/(sin(phi)*cos(phi - alpha));

rate_of_heat_generation_in_primary_zone = num2str(Qs);

display(rate_of_heat_generation_in_primary_zone);

% heat generation rate for, length of cut as thickness of chip, in primary zone

Qso = Qs*t2;

% Frictional force acting between the rake face and chip is given by

Ff = Fc*sin(alpha) + Ft*cos(alpha);

frictional_force = num2str(Ff);

display(frictional_force);

% Rate of heat generation in the secondary zone is:

Qf =(tau*h*Vw*sin(beta))/(cos(phi + beta - alpha)*sin(phi - alpha));

rate_of_heat_generation_in_secondary_zone = num2str(Qf);

display(rate_of_heat_generation_in_secondary_zone);

% Rate of heat generation within contact length of secondary zone is:

Qfo = Qf*cntct;

%--------------------------------------------------------------------------

%--------------------------------------------------------------------------

%------------------------------------

%Average temperature rise calculation

%------------------------------------

% Thermal conductivity of the workpiece in watts per meter per kelvin

Kc=177;

% Mass density of chip in kilograms per cubic meter

p=2785;

% specific heat capacity of chip in joules per kilogram per kelvin

Cc=875;

% Thermal Diffusivity

Sa = Kc/(p*Cc);

% Thermal number

Rt = (h*Vw)/Sa;

% fraction of heat flowing into the tool

X = 0.5 - (0.35* (log10(Rt*tan(phi))));

% Average temperature rise of the (((chip))) per unit depth of cut due to shearing

delta_T = ((1-X)*Qs)/(p*Cc*h*Vw);

average_temp_rise = num2str(delta_T);

display(average_temp_rise);

%This average temperature rise on the shear plane is used as a boundary

%condition at the upper left corner of the chip

%-------------------------------------------------------------------------

%--------------------------------------------------------------------------

%------------------

%Mesh generation

%------------------

% Chip velocity, for unit depth of cut, is given as

Vc = Qf/Ff;

chip_velocity = num2str(Vc);

display(chip_velocity);

% No of grids in x-direction

nbx = input('please enter no. of grids in x-direction (4 is default)=');

%No of grids in y-direction

nby = input('please enter no. of grids in y-direction (4 is default)=');

% No of nodes in x-direction

nbnx = nbx + 1;

% No of nodes in y-direction

nbny = nby + 1;

% proportion of frictional heat entering into the tool

Tio = 0.03;

% Grid spacing in x-direction

grsx = cntct/nbx;

% Grid spacing in y-direction

grsy = t2/nby;

% No. of nodes in the mesh

nod = nbnx*nbny;

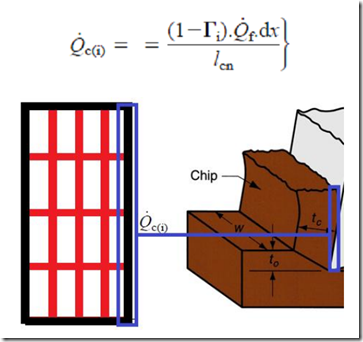

% heat flow rate in chip's primary control zone due to primary zone heat source is

Qrs = ((1-Tio)*Qs*grsy)/t2;

heat_flow_in_chip_node_due_to_shear_source=num2str(Qrs);

display(heat_flow_in_chip_node_due_to_shear_source);

% heat generation rate for a secondary node in chip due to frictional heat source

Qrf = ((1 - Tio)*Qf*grsx)/cntct;

heat_flow_in_chip_due_to_frictional_source=num2str(Qrf);

display(heat_flow_in_chip_due_to_frictional_source);

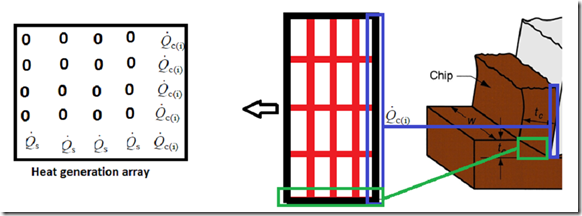

% Heat generation array

hga = [];

for i= 1:((sqrt(nod)));

hga(i,sqrt(nod)) = Qrf;

end

for j= 1:((sqrt(nod))-1)

for k = 1:(sqrt(nod)-1)

hga(k,j) = 0;

end

end

for m=1:(sqrt(nod)-1)

hga(sqrt(nod),m) = Qrs;

end

hga(sqrt(nod),sqrt(nod)) = Qrf + Qrs;

display(hga);

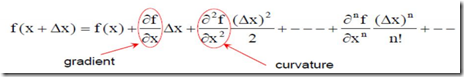

%temperature distribution within the chip

Am0 = (p*Cc*Vc)/(Kc);

Am1 = Am0/grsx;

Am2 = - (2/(grsx^2)) - (2/(grsy^2)) + Am1;

Am3 = (1/(grsx^2)) - (Am1);

Am4 = (grsx^2)*(grsy^2);

Am5 = Am4 * Am2;

Am6 = Am4 * Am3;

Am7 = grsy^2;

Am8 = grsx^2;

Am9 = Qrf/Kc;

A_1 = Am6/Am5;

A_2 = Am7/Am5;

A_3 = Am8/Am5;

A_4 = Am9/Am5;

A1 = -A_1;

A2 = -A_2;

A3 = -A_3;

A4 = -A_4;

for M = 1: (nbx - 1)

xM = M*grsx;

end

for N = 1: (nby - 1)

xN = N*grsy;

end

tempi = [];

% Boundary Condition

tempi(sqrt(nod),1) = delta_T;

% Data is imported from Solidworks 2012 by applying the boundary conditions

tempi = [344.1 345 346.1 347.3 350.3; 343 344.2 345.4 347.8 350.3; 339 336.9 343.9 348 351.2; 329.9 335.6 341.3 354.4 356.1; 234.5 343.1 352.7 362.4 370.6];

display(tempi);

% matrix of coefficients is given by

coeffik = (inv(tempi))*hga;

display(coeffik);

% Temperature distribution within the chip is given by multiplying inverse

% of coefficient matrix with heat generation array.

% plotting temperature

[x,y]=meshgrid(1:sqrt(nod),1:sqrt(nod));

surf(x,y,tempi)

%--------------------------------------------------------------------------

%THE END

%--------------------------------------------------------------------------

%--------------------------------------------------------------------------