Summary

In this article the summary of the developments about Elasto-hydrodynamic lubrication (EHL) is given. Two types; starved EHL and grease EHL are highlighted in this article. EHL is the type of lubrication that occurs in lubricated contra formal contacts where the elastic deformation of the lubricated surfaces has a substantial influence on the thickness of the lubricating film. EHL is very important in order to produce less expensive, more efficient and environment friendly products. The history of EHL started when Reynolds derived the differential equation describing the pressure distribution and load carrying capacity of lubricating films for journal bearings. Later on many scientists proposed many procedures to explain full film lubrication and finally the concept of amplitude reduction opened the possibilities to apply EHL theory to real surface roughness by means of fast Fourier transform methodology.

This paper describes the relationship of lubricant’s density with temperature and its pressure. It is to be noted that density variation with respect to temperature change is not considered in this paper. Density variation with pressure is nearly linear at low pressure. This paper also gives a brief review about the numerical method that are used to solve the mathematical problems regarding EHL. But due to high computing costs and solution convergence issues engineer tries to find the analytical solutions to these equations. The calculation of reduced pressure, dimensionless pressure and thickness of the thin film is done by considering simple assumptions regarding lubricant and applying Reynolds equation. This method does not provide the information about the exact thickness of film and also unable to identify its location. To overcome this problem, Greenwood introduced another assumption that the pressure and its distribution can be approximated by considering the elastic solution. To evaluate the outlet pressure he referred the concepts of fracture mechanics. After that paper describes some techniques which are used to measure the thickness of the film. This can be done by using high resolution and slow speed cameras. In this technique, it is necessary that one of meeting surfaces must be transparent.

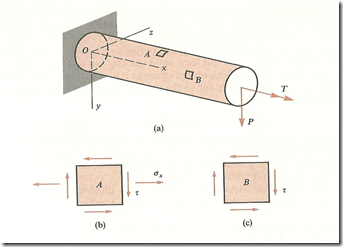

As we are reviewing the Elasto-Hydrodynamic lubrication theory, so it is important to analyze it from different aspects. One of the most important factor is 'Inlet Shear heating'. When a bearing operates, then the lubricant is squeezed due to load supported by bearing. But the journal within the bearing not only rotates but also slides to some extent. Due to this sliding action some of the fluid is rejected back to its earlier position, at the point of contact. This rejected fluid slides over the incoming fluid, due to which heat is generated within the lubricant due to shear effect. This shear heating effect must be considered for proper review of EHL theory.

Actually classical EHL theory is based on Newtonian fluid. In other words the temperature rise due to sliding is not considerd. This theory fails in the case of sliding. So to predict the accurate results, non-newtonian fluid must be considered with implementation of energy equation for the calculation of temperature. 'Kim' reduced the 3D heat transfer problem to 2D by assuming parabolic distribution of temperature across the film thickness, but this leads to inaccurate results.

The prediction of friction at point of contact is also important. The main cause of friction is the sliding of boundary layer on bearing. Also the surface topography plays important role in analyzing the friction. To predict the generated temperature several models are proposed. One of them is the 'one point model'. Firstly a researcher 'Jacod' reported master curves determined by interpolating the data using numerical techniques. After that, these master curves are used to determine the situation of parameters at point of contact, so geometry of contact becomes irrelevant. Also two dimensional model is proposed which considers oil conduction along the normal direction, by discretizing the geometry of contact and evaluating the heat at discrete points.

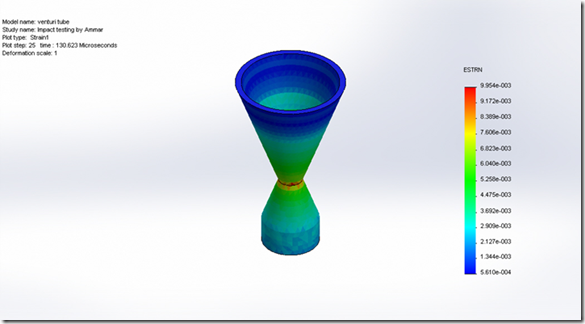

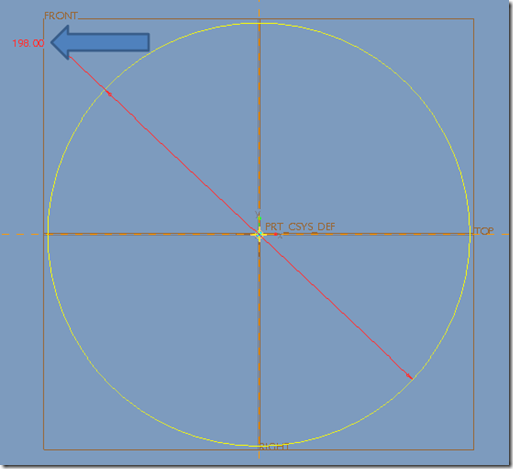

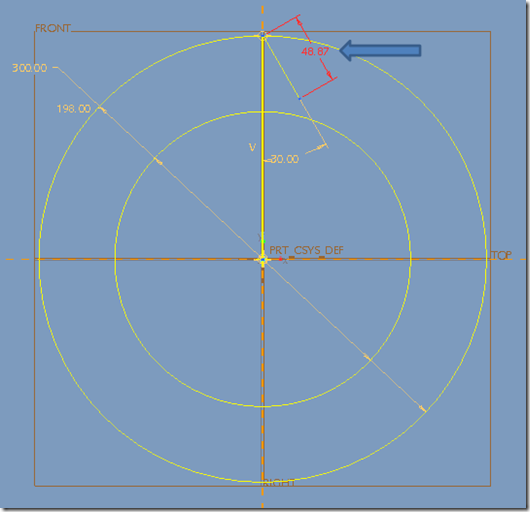

During its operation, some pressure waves are generated within the lubricant due to applied load. These waves decays with displacement from point of contact. It is predicted that this decay is exponential. So to properly review the EHL theory it is necessary to consider the effect of these pressure/discontinuties waves by expressing there parametrs in a function which is used to calculate the pressure.

The analysis of dimpled surface is also necessary to understand the EHL theory properly. It is investigated that, specimens with isotropic surfaces are better than superfinished specimens, when subjected to peeling test. Actually dimpled surfaces would induce pressure spikes, resulting in concentrated stresses. These stresses are the main cause of crack within the bearing. But in some cases, the lubricant fills the pits and try to enhance the revolution of journal within the bearing. This case is true for starved lubrication. Sometimes the pits are intentionally introduced to overcome the danger of starved lubrication.

Moreover in this paper, all the historical work done on the topic is discussed and their limitations as well. The limitations were present due to the fact that the factors like fatigue, pressure, EHL, Micro EHL were evaluated simultaneously particularly in a competitive to the failure. With the each new consideration a new model was developed like, Molecular dynamic model, CFD and Thin-film fluid model. However several phenomena are still undiscovered. Finally in this paper it is hoped that the engineers may find these three models working together to explore the failure of lubrication film in near future.