Date: Tuesday, May 07, 2013

Designer: Ammar Aziz Study name: Impact testing by Ammar Analysis type: Drop Test

Disclaimer: The results of this simulation can not be used for any practical implementation.

| Solid Body | |||

| Document Name and Reference | Treated As | Volumetric Properties | Document Path/Date Modified |

| Venturi Impact | Solid Body | Mass:0.190265 kg Volume:0.00013399 m^3 Density:1420 kg/m^3 Weight:1.8646 N |

May 07 12:56:49 2013 |

Study Properties

| Study name | Venturi Impact |

| Analysis type | Drop Test |

| Mesh type | Solid Mesh |

| Large displacement | On |

| Result folder | SolidWorks document |

Setup Information

| Type | Drop height |

| Drop Height from Centroid | 2000 mm |

| Gravity | 9.81 m/s^2 |

| Gravity Reference | Top Plane |

| Friction Coefficient | 0 |

| Target Stiffness | Rigid target |

| Critical Damping Ratio | 0 |

Drop height is selected from the automatically detected geometric center of tube to the floor surface. So please not confuse this length with the distance between the lower portion of tube and floor surface

Also the friction between the tube and floor is neglected. This assumption is based on another assumption that tube is falling perfectly vertically, so that there is no side thrust which enhances the friction process during the impact.

The floor is assumed to be rigid. It implies all the potential energy of the tube is dissipated into the floor without any rejection of energy by floor back to tube.

Result Options

| Solution Time After Impact | 130.7 microsec |

| Save Results Starting From | 0 microsec |

| No. of Plots | 25 |

| No. of Graph Steps Per Plot | 20 |

| Number of vertex | 0 |

The simulated result span is b/w time of impact to 130 lacth second after the impact

Units

| Unit system: | SI (MKS) |

| Length/Displacement | mm |

| Temperature | Kelvin |

| Angular velocity | Rad/sec |

| Pressure/Stress | N/mm^2 (MPa) |

Material Properties

| Model Reference | Properties | Components | ||||||||||||||||

| |

| SolidBody 1(Shell3)(venturi tube) |

The model is assumed to be linear elastic and isotropic. It implies Hook’s law is valid during the entire simulation. Elastic modulus of material is approximately 3GPa.

Mesh Information

| Mesh type | Solid Mesh |

| Mesher Used: | Standard mesh |

| Automatic Transition: | Off |

| Include Mesh Auto Loops: | Off |

| Jacobian points | 4 Points |

| Element Size | 0.00511862 m |

| Tolerance | 0.000255931 m |

| Mesh Quality | High |

Mesh Information - Details

| Total Nodes | 13311 |

| Total Elements | 15359 |

| Maximum Aspect Ratio | 5.3887 |

| % of elements with Aspect Ratio < 3 | 99.5 |

| % of elements with Aspect Ratio > 10 | 0 |

| % of distorted elements(Jacobian) | 0 |

| Time to complete mesh(hh;mm;ss): | 00:00:21 |

It is a fine mesh with no distorted element. All the elements are less than aspect ratio of 3. Approximately 13 thousand nodes. So a good solution is expected.

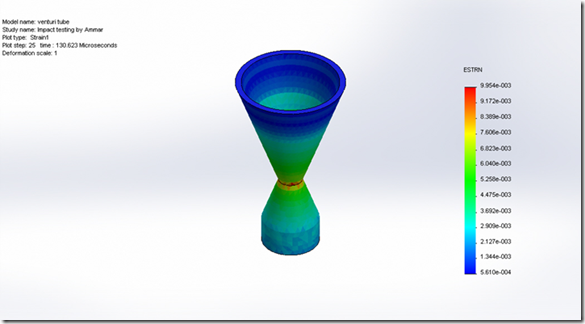

Study Results

| Name | Type | Min | Max |

| Stress1 | VON: von Mises Stress | 1.50947 N/mm^2 (MPa) Node: 1927 | 35.3117 N/mm^2 (MPa) Node: 7042 |

As the maximum stress generated due to impact is approximately 35 MPa which is well below the tensile strength of 3GPa. So our model is safe. But the neck is critical is the tube falls from more high heights.

| Name | Type | Min | Max |

| Strain1 | ESTRN: Equivalent Strain | 0.000561001 Element: 2362 | 0.00995434 Element: 3707 |

Conclusion:

you can see the most sensitive location is the neck of venturi tube if it falls from certain height vertically according to above scheme.

Disclaimer:

This simulation is just to describe the capability of solid works to simulate the impact test. Also it encourages the sound theoretical knowledge development.

Ammar, yar nice work....

ReplyDeleteThankyou Ali Zahid

DeleteThankyou Ali Zahid...

ReplyDeleteHarrah's Casino & Racetrack - MapYRO

ReplyDeleteHarrah's Cherokee Casino & Racetrack is located just south of Asheville on the shores 구미 출장샵 of the 오산 출장샵 Great 제주도 출장샵 Smoky Mountains of Western North Carolina. The 강릉 출장마사지 casino 포천 출장안마 and racetrack