Sections:

1.What is a Flexible Manufacturing System?

2.FMS Components

3.FMS Applications and Benefits

4.FMS Planning and Implementation Issues

5.Quantitative Analysis of Flexible Manufacturing Systems

Where to Apply FMS Technology

If

-the plant presently either:

–Produces parts in batches or

–Uses manned GT cells and management wants to automate the cells

-It must be possible to group a portion of the parts made in the plant into part families

–The part similarities allow them to be processed on the FMS workstations

-Parts and products are in the mid-volume, mid-variety production range

Flexible Manufacturing System - Defined

A highly automated GT machine cell, consisting of a group of processing stations (usually CNC machine tools), interconnected by an automated material handling and storage system, and controlled by an integrated computer system

-The FMS relies on the principles of GT

–No manufacturing system can produce an unlimited range of products

–An FMS is capable of producing a single part family or a limited range of part families

Flexibility Tests in an Automated Manufacturing System

To qualify as being flexible, a manufacturing system should satisfy the following criteria (“yes” answer for each question):

1.Can it process different part styles in a non‑batch mode?

2.Can it accept changes in production schedule?

3.Can it respond gracefully to equipment malfunctions and breakdowns?

4.Can it accommodate introduction of new part designs?

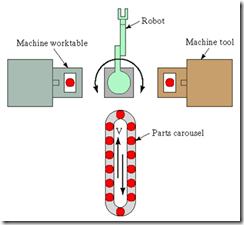

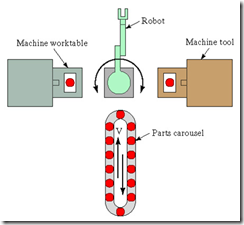

Automated manufacturing cell with two machine tools and robot. Is it a flexible cell?

Is the Robotic Work Cell Flexible?

1.Part variety test

–Can it machine different part configurations in a mix rather than in batches?

2.Schedule change test

–Can production schedule and part mix be changed?

-Is the Robotic Work Cell Flexible?

3.Error recovery test

-Can it operate if one machine breaks down?

•Example: while repairs are being made on the broken machine, can its work be temporarily reassigned to the other machine?

4.New part test

–As new part designs are developed, can NC part programs be written off‑line and then downloaded to the system for execution?

Types of FMS

•Kinds of operations

–Processing vs. assembly

–Type of processing

•If machining, rotational vs. non-rotational

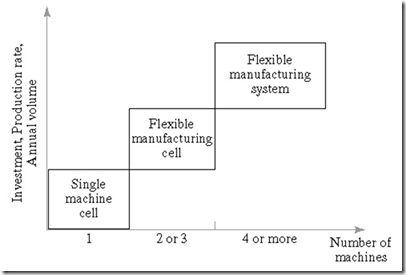

•Number of machines (workstations):

1.Single machine cell (n = 1)

2.Flexible manufacturing cell (n = 2 or 3)

3.Flexible manufacturing system (n = 4 or more)

Single-Machine Manufacturing Cell

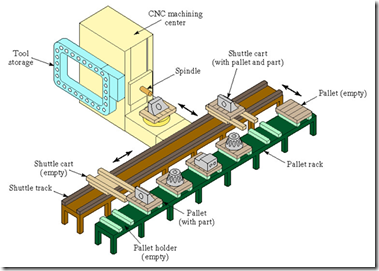

A single-machine CNC machining cell (photo courtesy of Cincinnati Milacron)

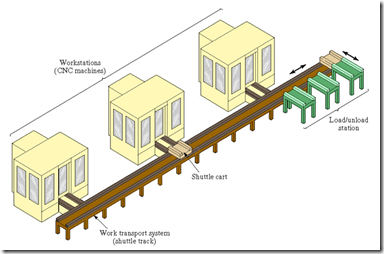

Flexible Manufacturing Cell

A two-machine flexible manufacturing cell for machining (photo courtesy of Cincinnati Milacron)

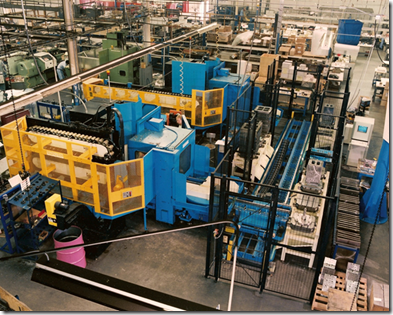

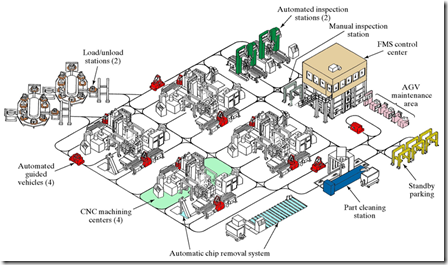

A five-machine flexible manufacturing system for machining (photo courtesy of Cincinnati Milacron)

Features of the Three Categories

FMS Types

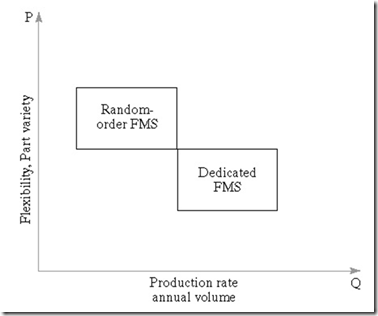

Level of Flexibility

1.Dedicated FMS

–Designed to produce a limited variety of part styles

–The complete universe of parts to be made on the system is known in advance

–Part family likely based on product commonality rather than geometric similarity

2.Random-order FMS

–Appropriate for large part families

–New part designs will be introduced

–Production schedule is subject to daily changes

•Dedicated vs. Random-Order FMSs

FMS Components

1.Workstations

2.Material handling and storage system

3.Computer control system

4.Human labor

Workstations

•Load and unload station(s)

–Factory interface with FMS

–Manual or automated

–Includes communication interface with worker to specify parts to load, fixtures needed, etc.

•CNC machine tools in a machining type system

–CNC machining centers

–Milling machine modules

–Turning modules

•Assembly machines

Material Handling and Storage

•Functions:

–Random, independent movement of parts between stations

–Capability to handle a variety of part styles

•Standard pallet fixture base

•Workholding fixture can be adapted

–Temporary storage

–Convenient access for loading and unloading

–Compatibility with computer control

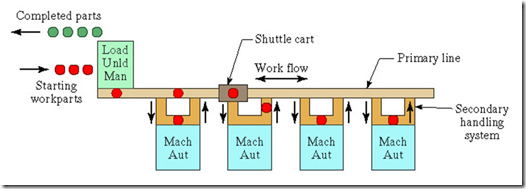

•Material Handling Equipment

•Primary handling system establishes basic FMS layout

•Secondary handling system - functions:

–Transfers work from primary handling system to workstations

–Position and locate part with sufficient accuracy and repeatability for the operation

–Reorient part to present correct surface for processing

–Buffer storage to maximize machine utilization

Five Types of FMS Layouts

•The layout of the FMS is established by the material handling system

•Five basic types of FMS layouts

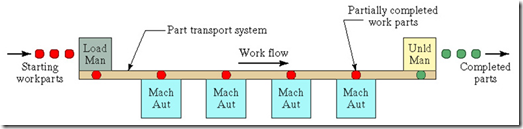

1.In‑line

2.Loop

3.Ladder

4.Open field

5.Robot‑centered cell

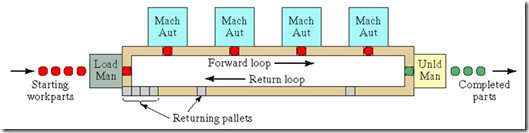

•FMS In-Line Layout

•Straight line flow, well-defined processing sequence similar for all work units

•Work flow is from left to right through the same workstations

•No secondary handling system

•Linear transfer system with secondary parts handling system at each workstation to facilitate flow in two directions

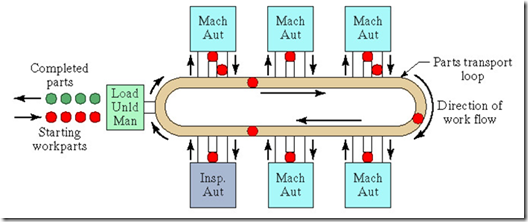

•FMS Loop Layout

•One direction flow, but variations in processing sequence possible for different part types

•Secondary handling system at each workstation

•FMS Rectangular Layout

•Rectangular layout allows recirculation of pallets back to the first station in the sequence after unloading at the final station

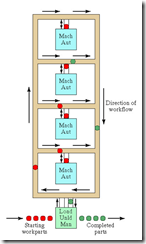

•FMS Ladder Layout

•Loop with rungs to allow greater variation in processing sequence

•FMS Open Field Layout

•Multiple loops and ladders, suitable for large part families

•Robot-Centered Cell

•Suited to the handling of rotational parts and turning operations

FMS Computer Functions

1.Workstation control

–Individual stations require controls, usually computerized

2.Distribution of control instructions to workstations

–Central intelligence required to coordinate processing at individual stations

3.Production control

–Product mix, machine scheduling, and other planning functions

4.Traffic control

–Management of the primary handling system to move parts between workstations

5.Shuttle control

–Coordination of secondary handling system with primary handling system

6.Workpiece monitoring

–Monitoring the status of each part in the system

•FMS Computer Functions

7.Tool control

–Tool location

•Keeping track of each tool in the system

–Tool life monitoring

•Monitoring usage of each cutting tool and determining when to replace worn tools

8.Performance monitoring and reporting

–Availability, utilization, production piece counts, etc.

9.Diagnostics

–Diagnose malfunction causes and recommend repairs

Duties Performed by Human Labor

•Loading and unloading parts from the system

•Changing and setting cutting tools

•Maintenance and repair of equipment

•NC part programming

•Programming and operating the computer system

•Overall management of the system

FMS Applications

•Machining – most common application of FMS technology

•Assembly

•Inspection

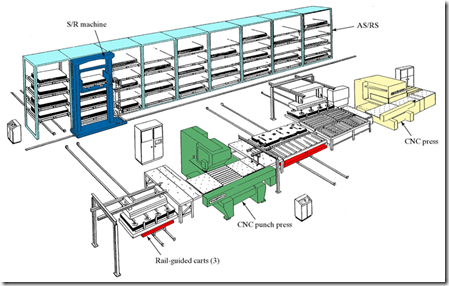

•Sheet metal processing (punching, shearing, bending, and forming)

•Forging

•FMS at Chance-Vought Aircraft (courtesy of Cincinnati Milacron)

FMS for Sheet Metal Fabrication

FMS Benefits

•Increased machine utilization

–Reasons:

•24 hour operation likely to justify investment

•Automatic tool changing

•Automatic pallet changing at stations

•Queues of parts at stations to maximize utilization

•Dynamic scheduling of production to account for changes in demand

•Fewer machines required

•Reduction in factory floor space required

•FMS Benefits

•Greater responsiveness to change

•Reduced inventory requirements

–Different parts produced continuously rather than in batches

•Lower manufacturing lead times

•Reduced labor requirements

•Higher productivity

•Opportunity for unattended production

–Machines run overnight ("lights out operation")

FMS Planning and Design Issues

•Part family considerations

–Defining the part family of families to be processed

•Based on part similarity

•Based on product commonality

•Processing requirements

–Determine types of processing equipment required

•Physical characteristics of workparts

–Size and weight determine size of processing equipment and material handling equipment

•Production volume

–Annual quantities determined number of machines required

•Types of workstations

•Variations in process routings

•Work-in-process and storage capacity

•Tooling

•Pallet fixtures

FMS Operational Issues

•Scheduling and dispatching

–Launching parts into the system at appropriate times

•Machine loading

–Deciding what operations and associated tooling at each workstation

•Part routing

–Selecting routes to be followed by each part

•

•FMS Operational Issues

•Part grouping

–Which parts should be on the system at one time

•Tool management

–When to change tools

•Pallet and fixture allocation

–Limits on fixture types may limit part types that can be processed

•Quantitative Analysis of

Flexible Manufacturing Systems

•FMS analysis techniques:

1.Deterministic models

2.Queueing models

3.Discrete event simulation

4.Other approaches, including heuristics

•Deterministic models

1.Bottleneck model - estimates of production rate, utilization, and other measures for a given product mix

2.Extended bottleneck model - adds work-in-process feature to basic model

•For a given part mix, the total production rate is ultimately limited by the bottleneck station

•If part mix ratios can be relaxed, it may be possible to increase total FMS production rate by increasing the utilization of non-bottleneck stations

•As a first approximation, bottleneck model can be used to estimate the number of servers of each type to achieve a specified overall production rate

Hello Flexible Manufacturing System- Introduction

ReplyDelete