One of the most important maintenance operation is shaft alignment. Approximately 50% of all costs related to breakdowns of machines with rotating shafts are caused by misalignment.

Types of misalignments:

1- Angular misalignment

2- Parallel misalignment

Misalignment means:

Increased bearing load, Reduction of bearing life, Increased wear of seals, bearings and couplings, Increased vibrations, Increased noise, Increased energy consumption, Shaft failures.

Bearing Fatigue:

A 20% load increase from misalignment reduces the calculated bearing life by almost 50%!

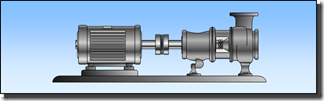

Main applications of shaft alignment:

Electric motors, Turbines, Electric generators, Pumps, Blowers and fans, Compressors, Gearboxes

Some Rough alignment methods:

1- Visual 2- Feeler gauges

The main advantage of above mentioned methods is speed. On the other hand, disadvantage is poor accuracy.

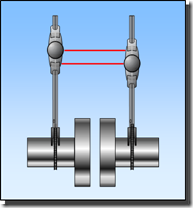

Dial indicators method:

1- Reversed indicator method 2- Rim and face method

The main advantage of this method is accuracy but it is relatively time consuming.

Laser shaft alignment method:

It is an accurate as well as less time consuming method.

Requirements for laser alignment equipment:

extended personal customer visits, complete demonstration

and training, expert salespeople and/or product managers.

Many customers who need alignment but use traditional methods because they think that laser alignment is very expensive!

Big customers who use only one advanced laser shaft alignment system because of the price but they actually need more.

SKF shaft alignment series:

USER FRIENDLY TOOL:

only five buttons to operate, interactive display, standard with a printer, clear printout for documentation, easy fitting with chain, fixtures, less components, very descriptive manual.

LESS COMPONENTS:

display unit, printer, 2 measuring units with spirit levels and cables, chain fixtures, measuring tape, set of shims.

No comments:

Post a Comment